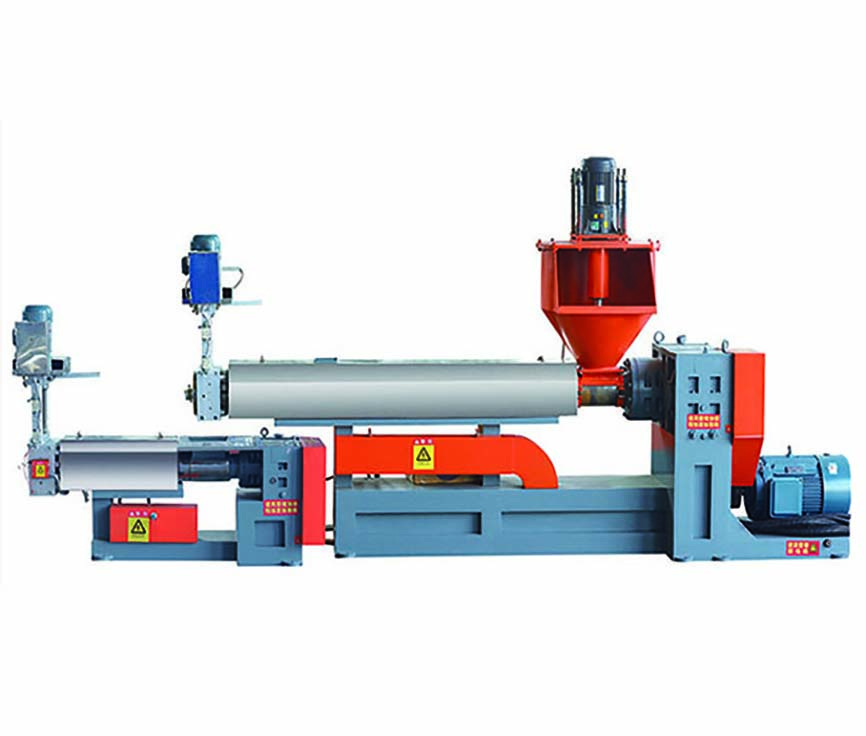

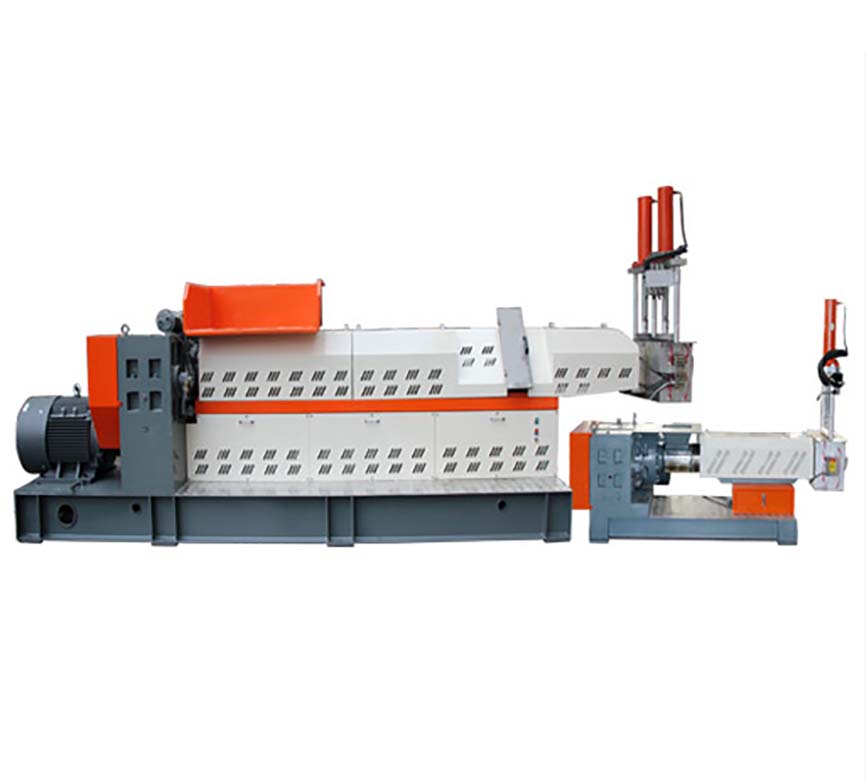

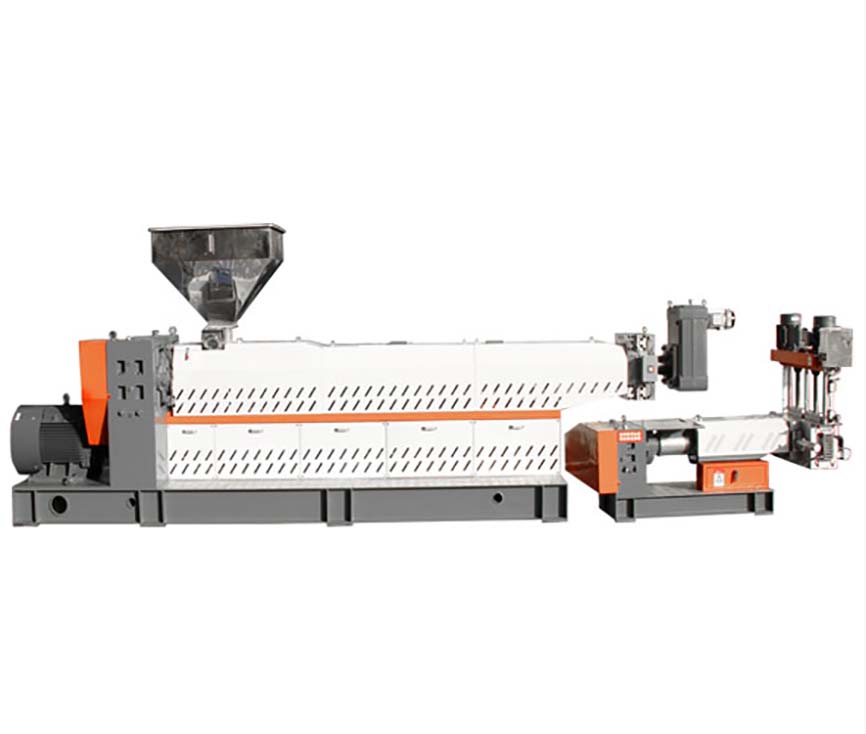

Uses: 1: Mainly used for plastic film such as HDPE LDPE PP after washing and granulating.

2: It can be used for granulation of nylon waste silk, socks, cloth, woven bags, non-woven fabrics and mesh materials.

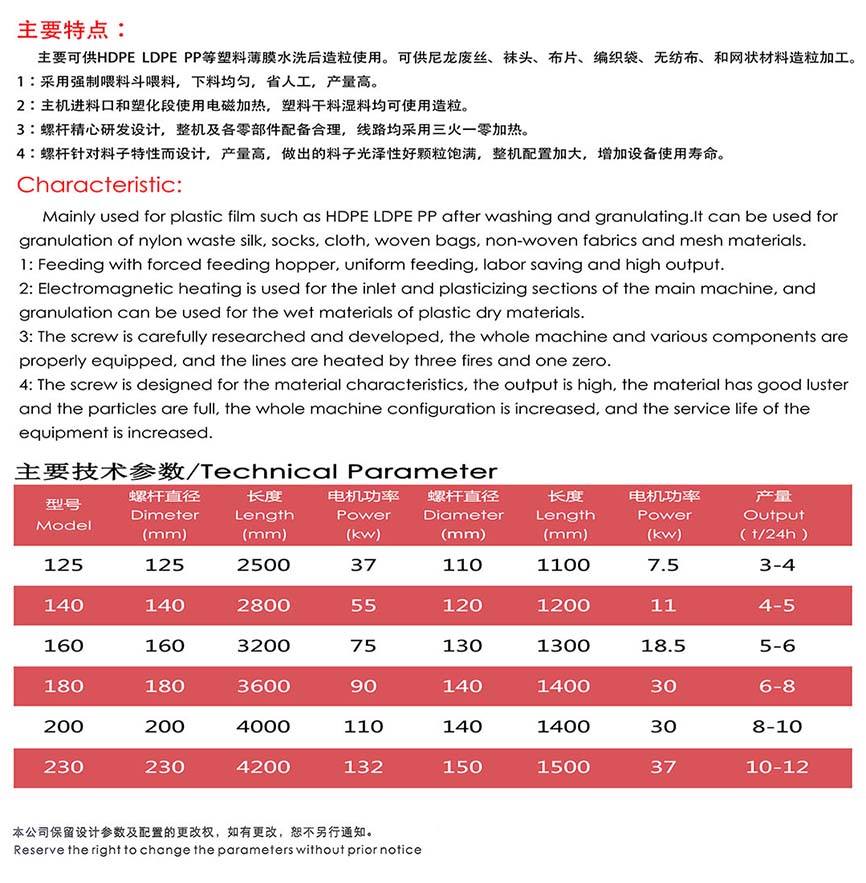

Features:

1: Feeding with forced feeding hopper, uniform feeding, labor saving and high output.

2: Electromagnetic heating is used for the inlet and plasticizing sections of the main machine, and granulation can be used for the wet materials of plastic dry materials.

3: The screw is carefully researched and developed, the whole machine and various components are properly equipped, and the lines are heated by three fires and one zero.

4: The screw is designed for the material characteristics, the output is high, the material has good luster and the particles are full, the whole machine configuration is increased, and the service life of the equipment is increased.

5: The granulator has the characteristics of high output and low energy consumption. It is equipped with a large torque reducer and motor. The screw of this machine has been specially designed to have no dead angle and no iron effect, which effectively improves the production capacity and increases the plasticizing effect of plastic. Exhaust, double exhaust structure, dry material, damp material, water washing material can fully drain and exhaust, so that the particles are strong and full of gloss.

6: High-quality electrical and drive equipment makes the equipment safer and more reliable in use.

Main products: plastic granulator production line equipment, plastic granulator, plastic granulator, feeding iron machine, vertical mixer, die changer, pulverizer, vertical dewatering machine, sleeve screw, stainless steel Sinks, pallets, vertical fans, air supply storage bins, color mixing machines, vibrating screens, shakers, pelletizers and other equipment and accessories.